According to the German Engineering Federation (VDMA), intralogistics or in-plant logistics encompasses the organization, control, implementation and optimization of material flow, information flows and the handling of goods within a company. Our solutions for intralogistics can be assigned to the area of in-house material transport and material handling and contribute to an optimized material flow.

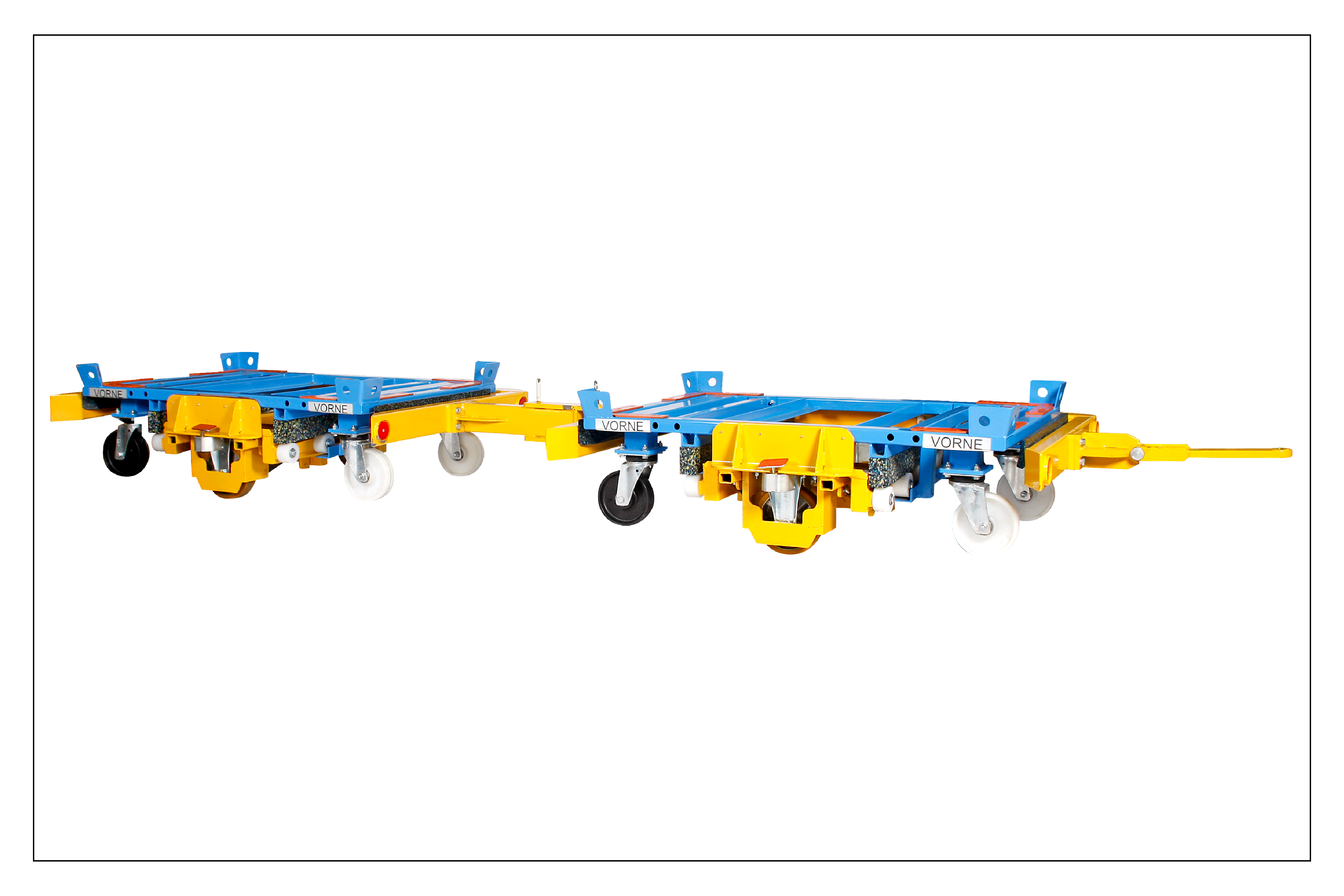

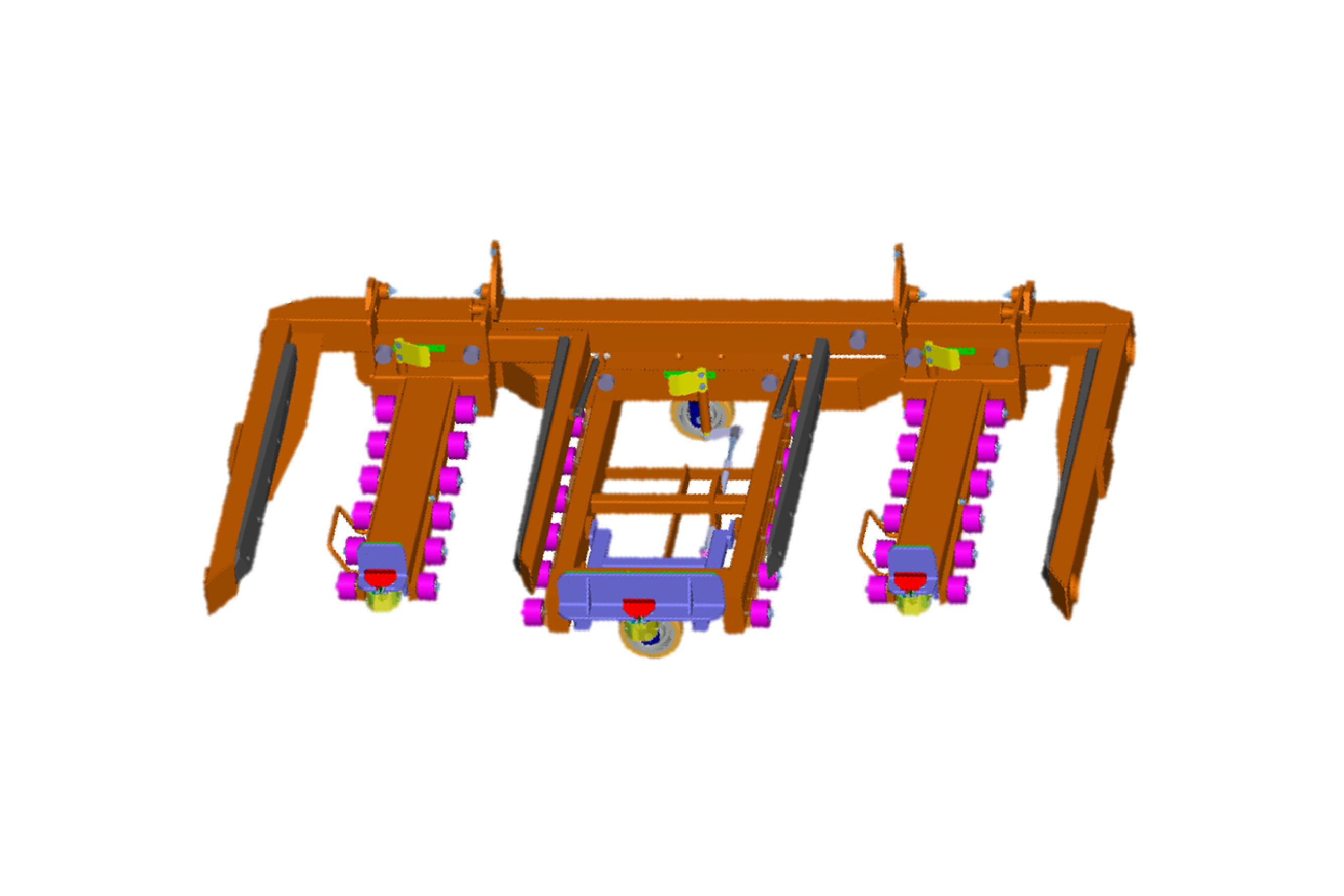

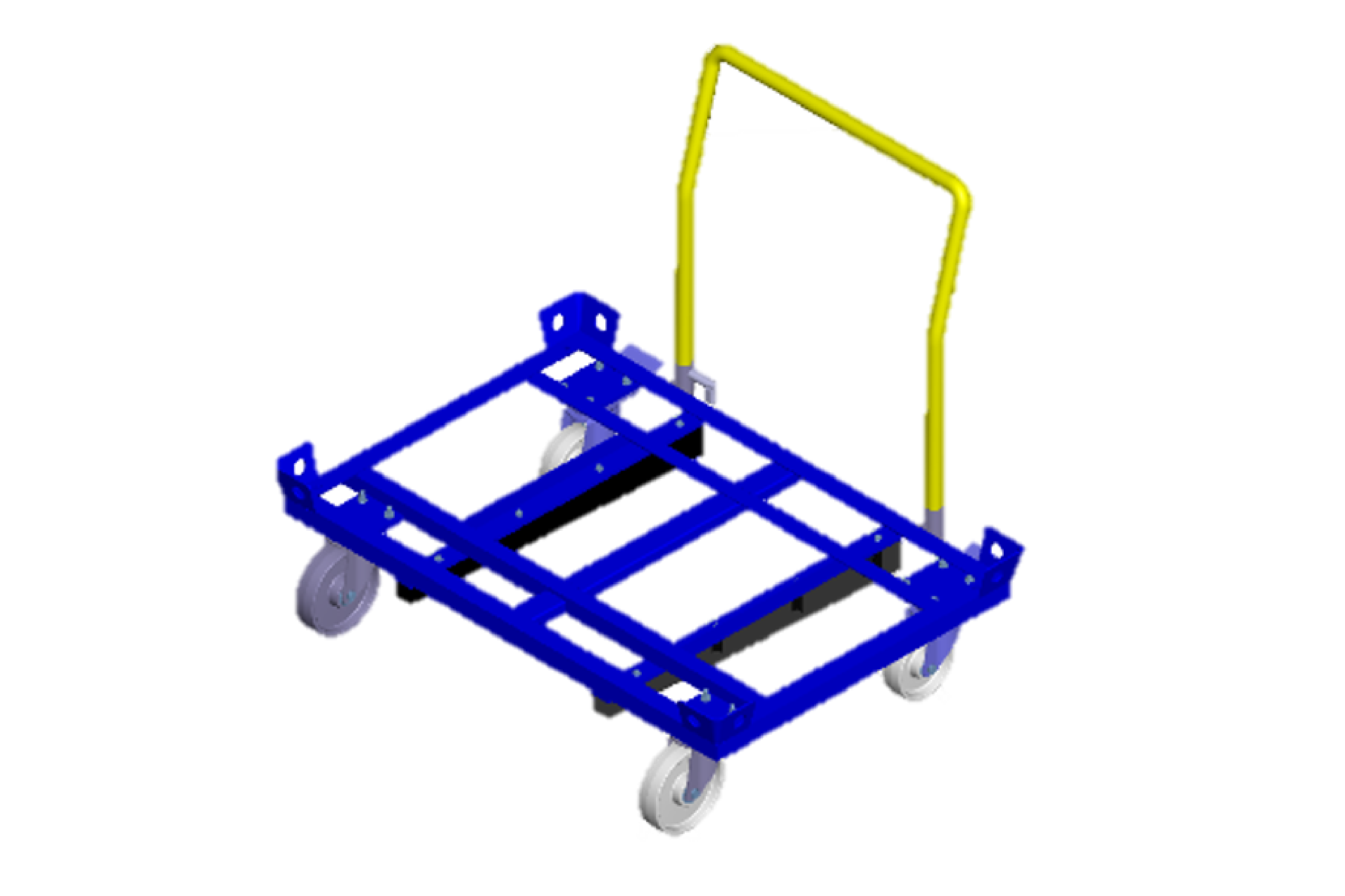

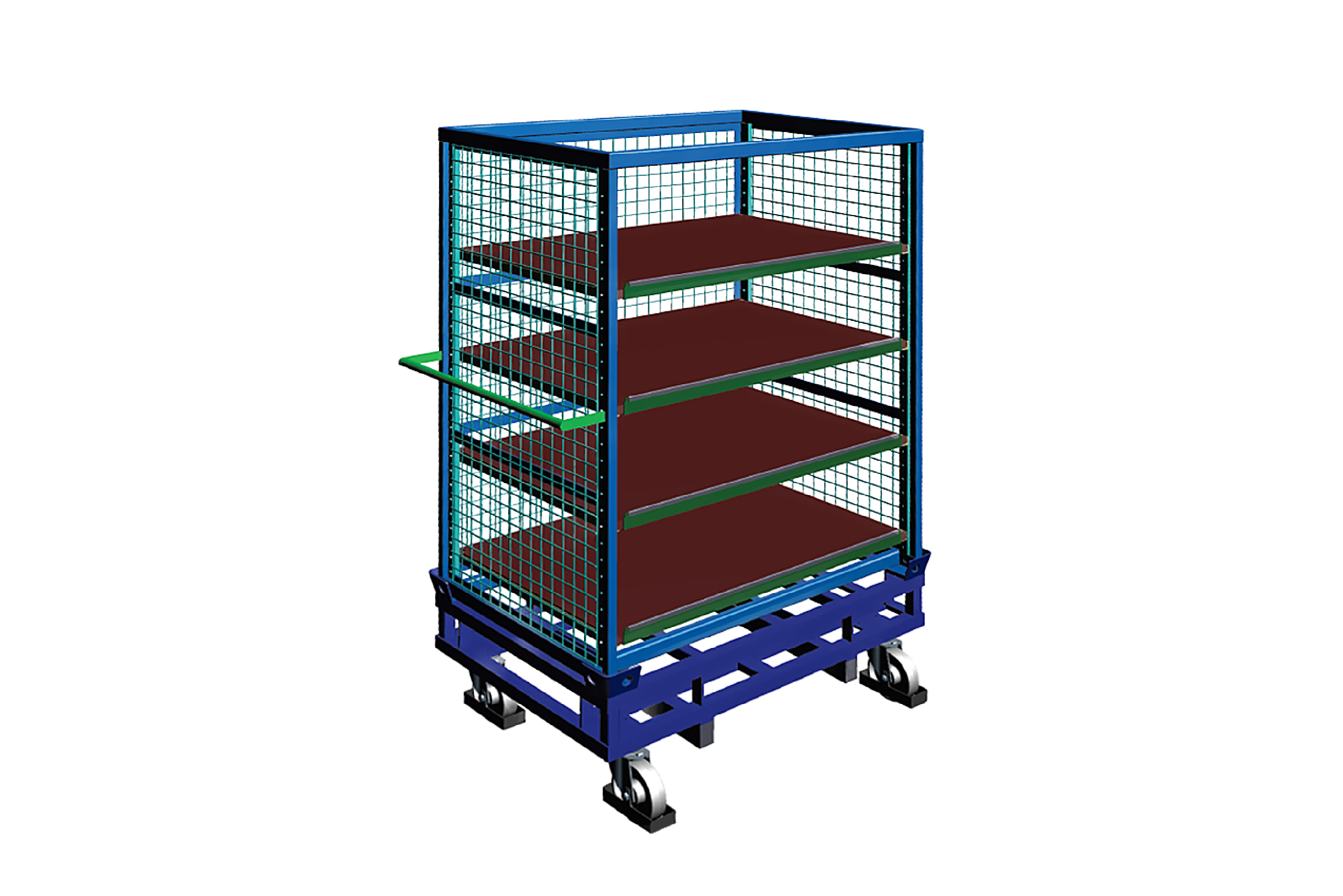

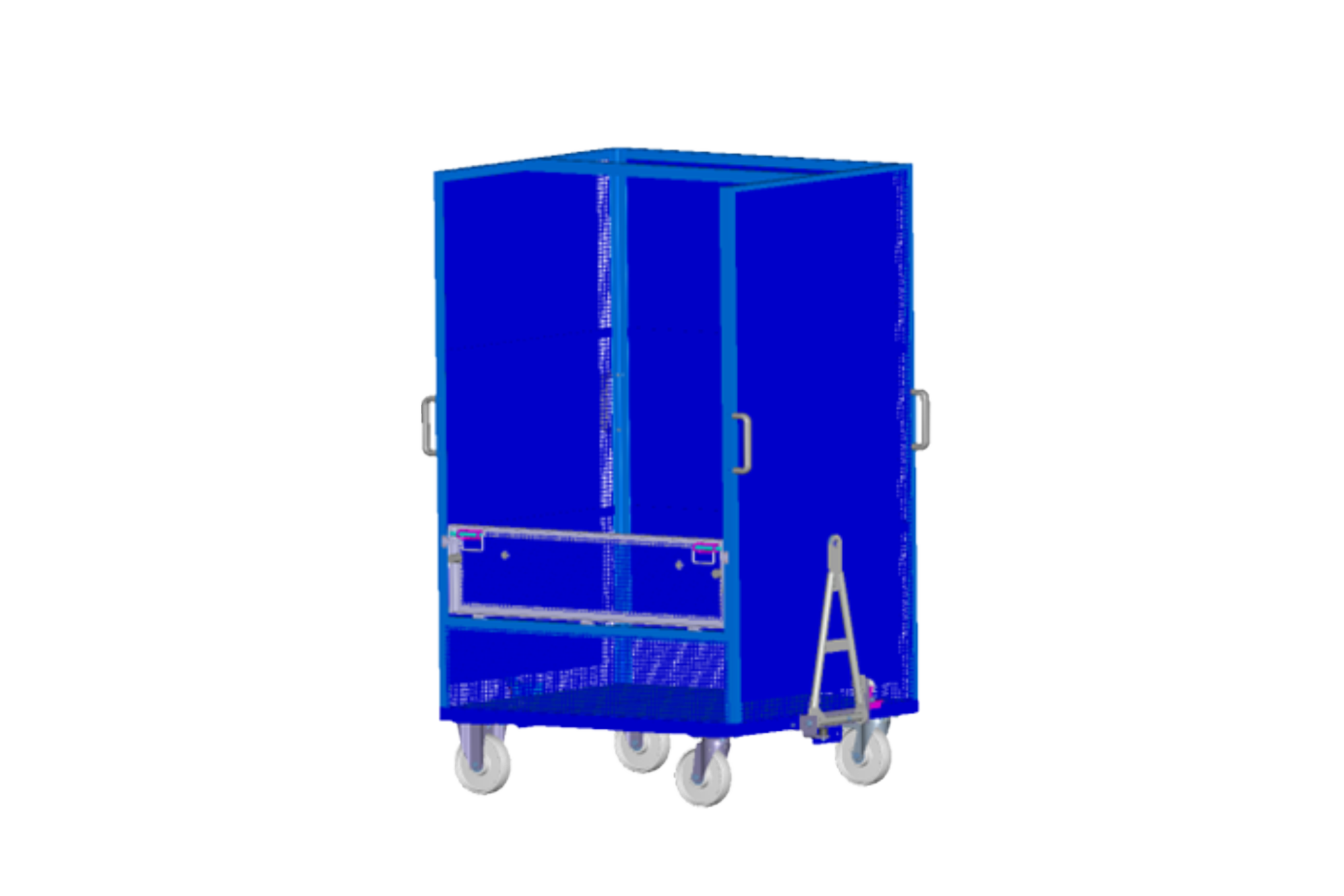

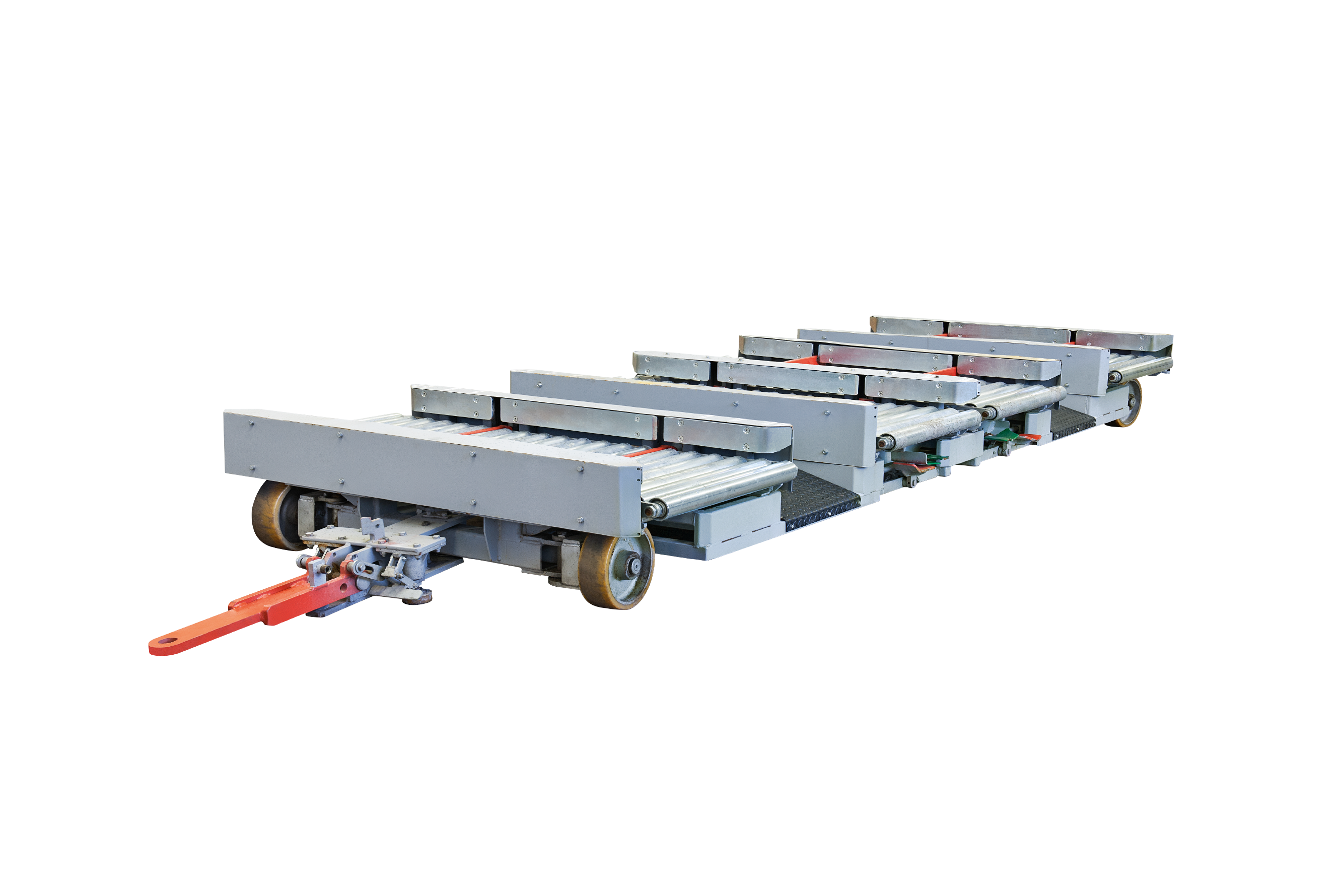

The tugger train systems and carts are designed for flexible transport and handling of containers. With the help of an industrial truck with a tugger train, goods grouped in racks can be transported to the place where they are needed. On site, they can be maneuvered with manual push carts.

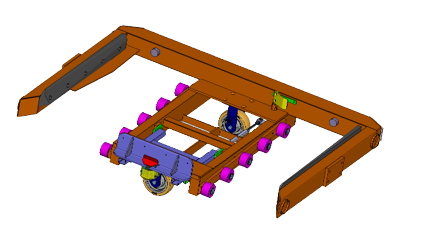

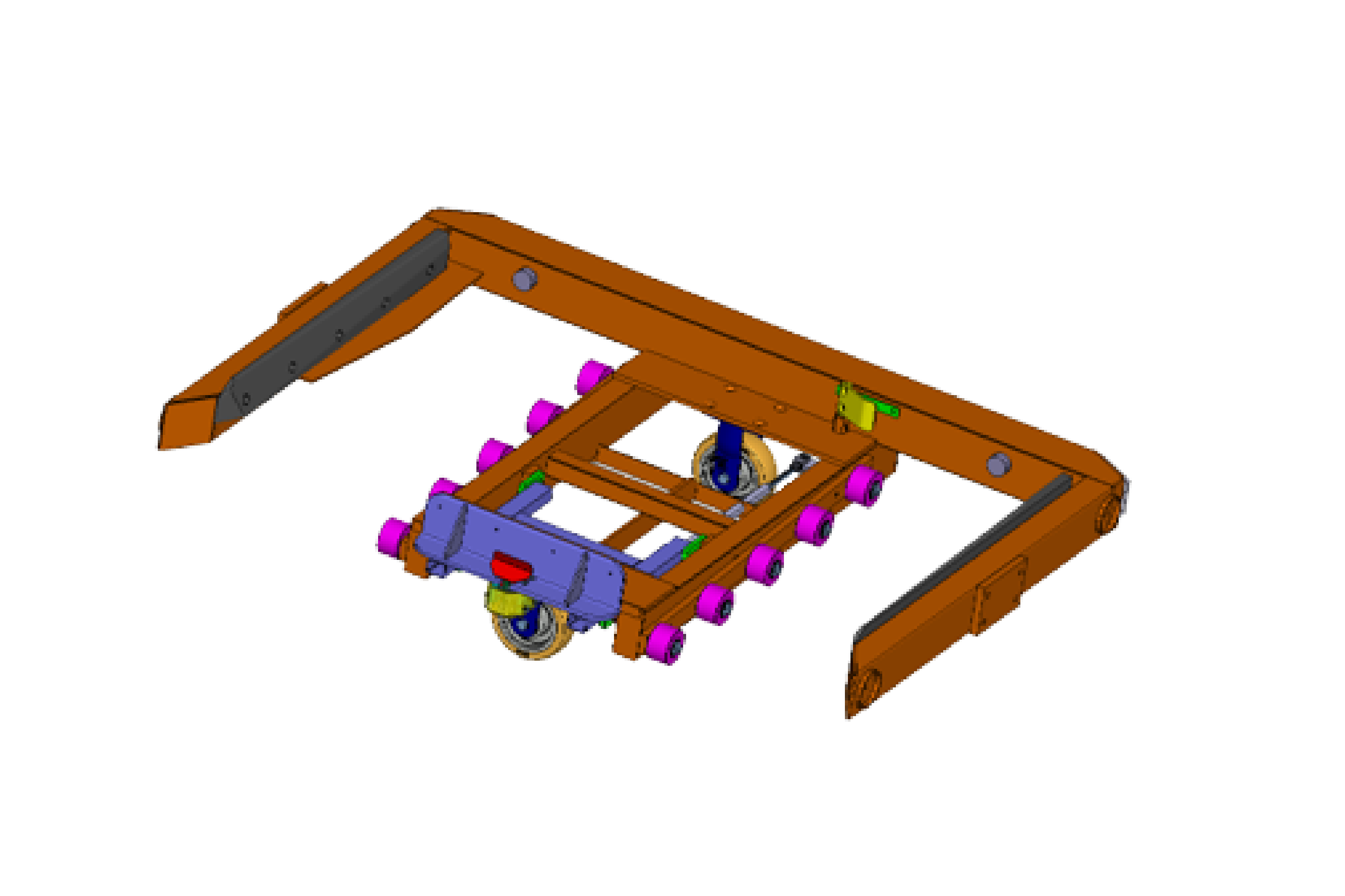

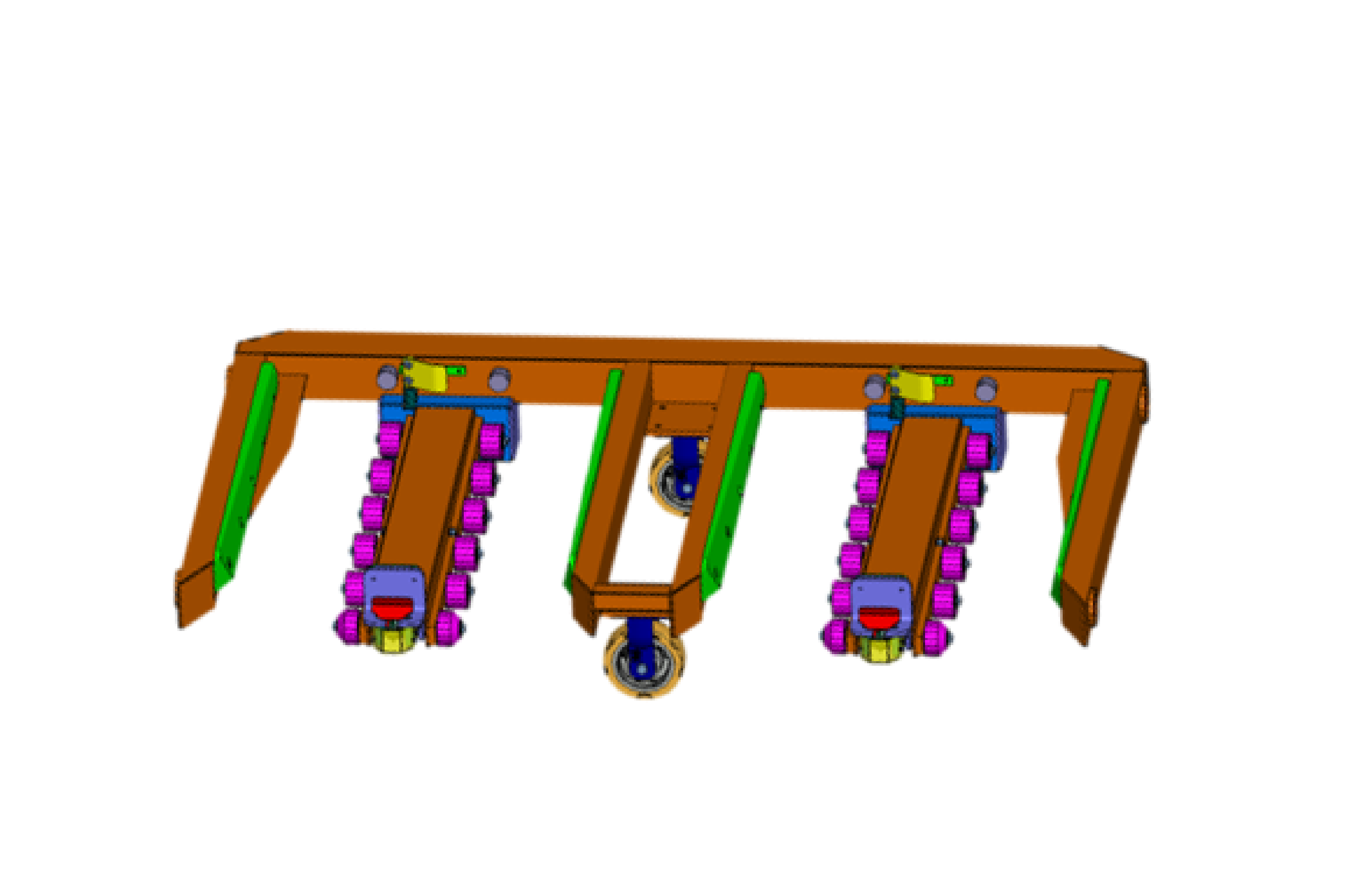

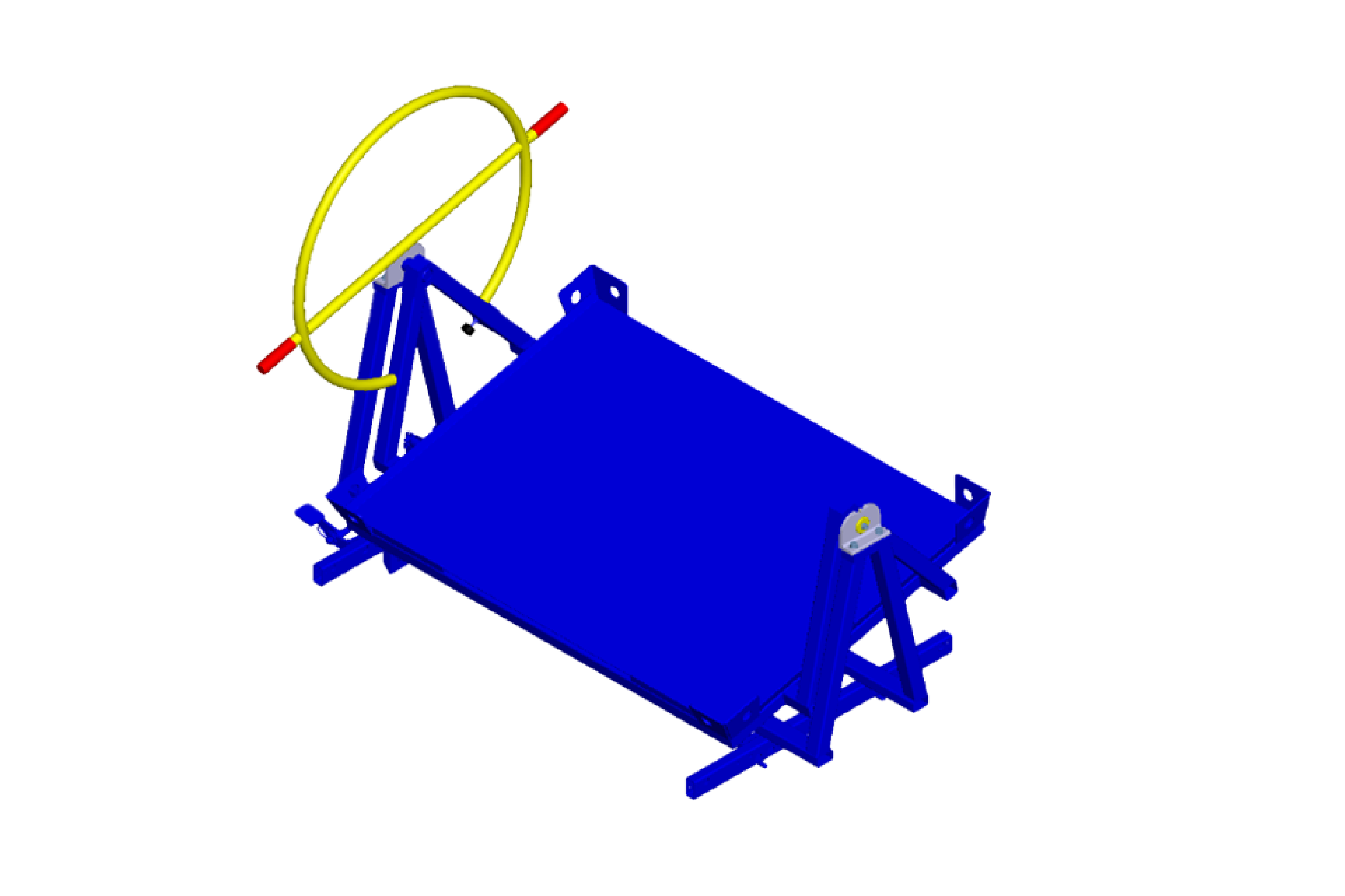

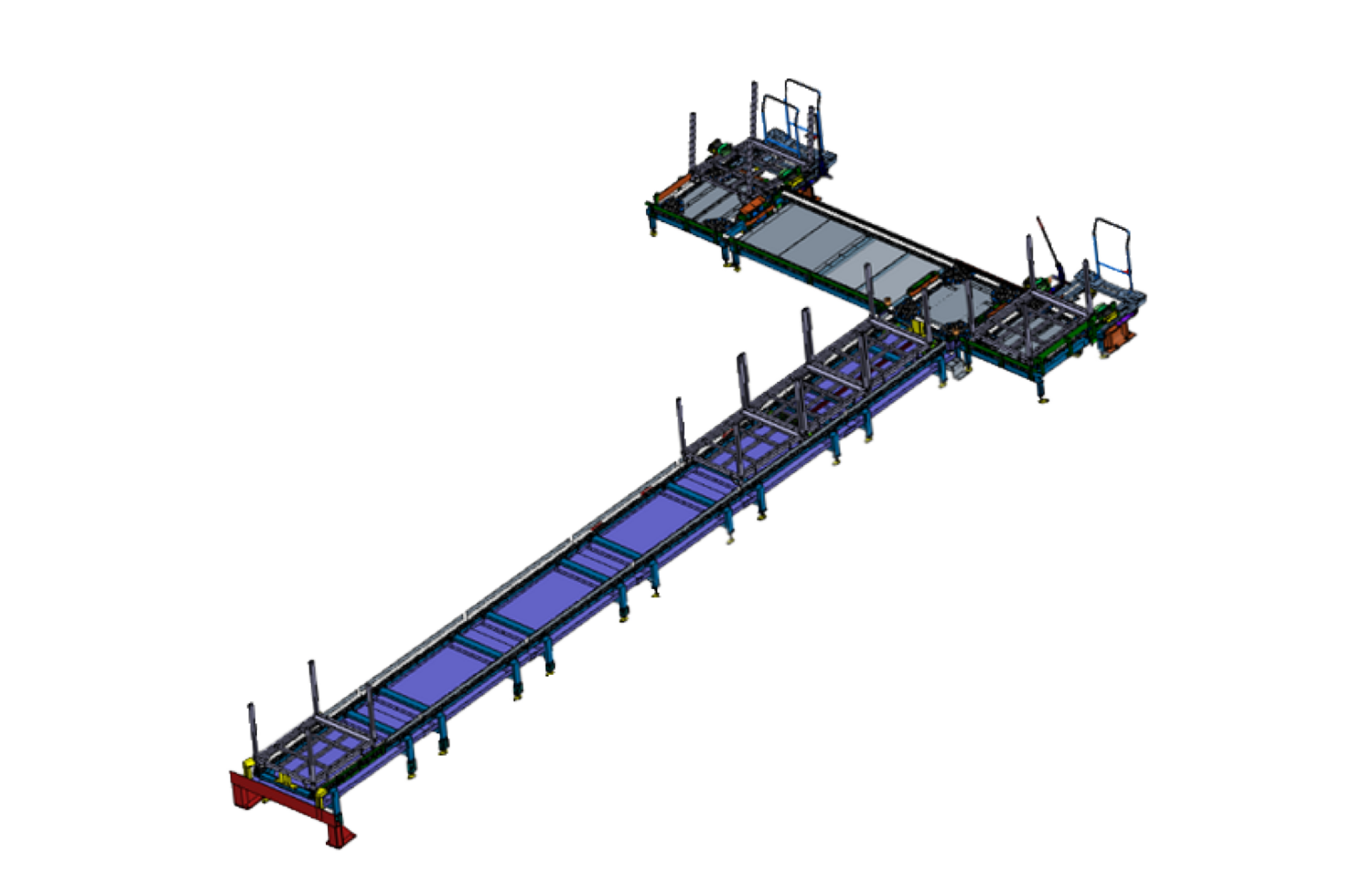

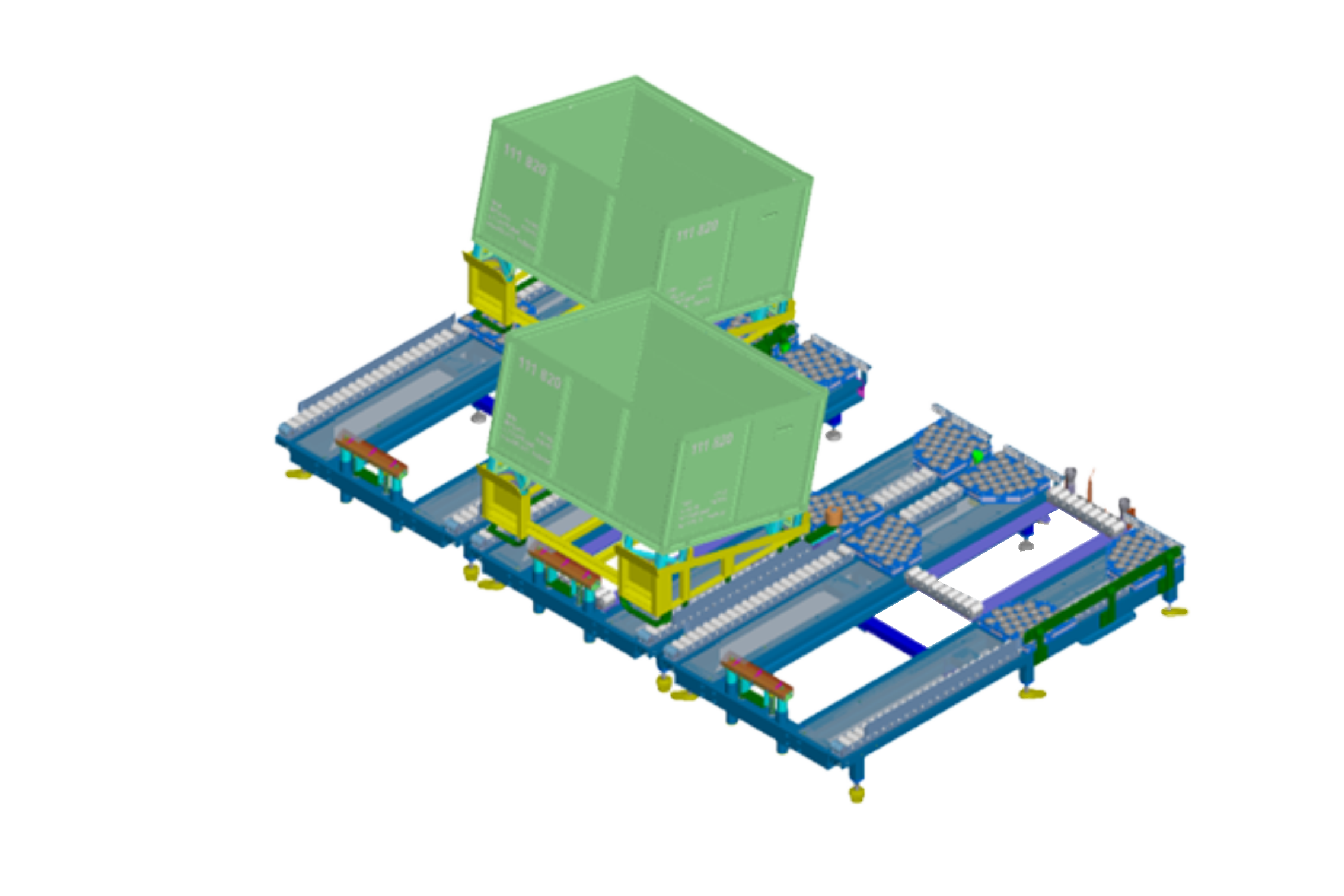

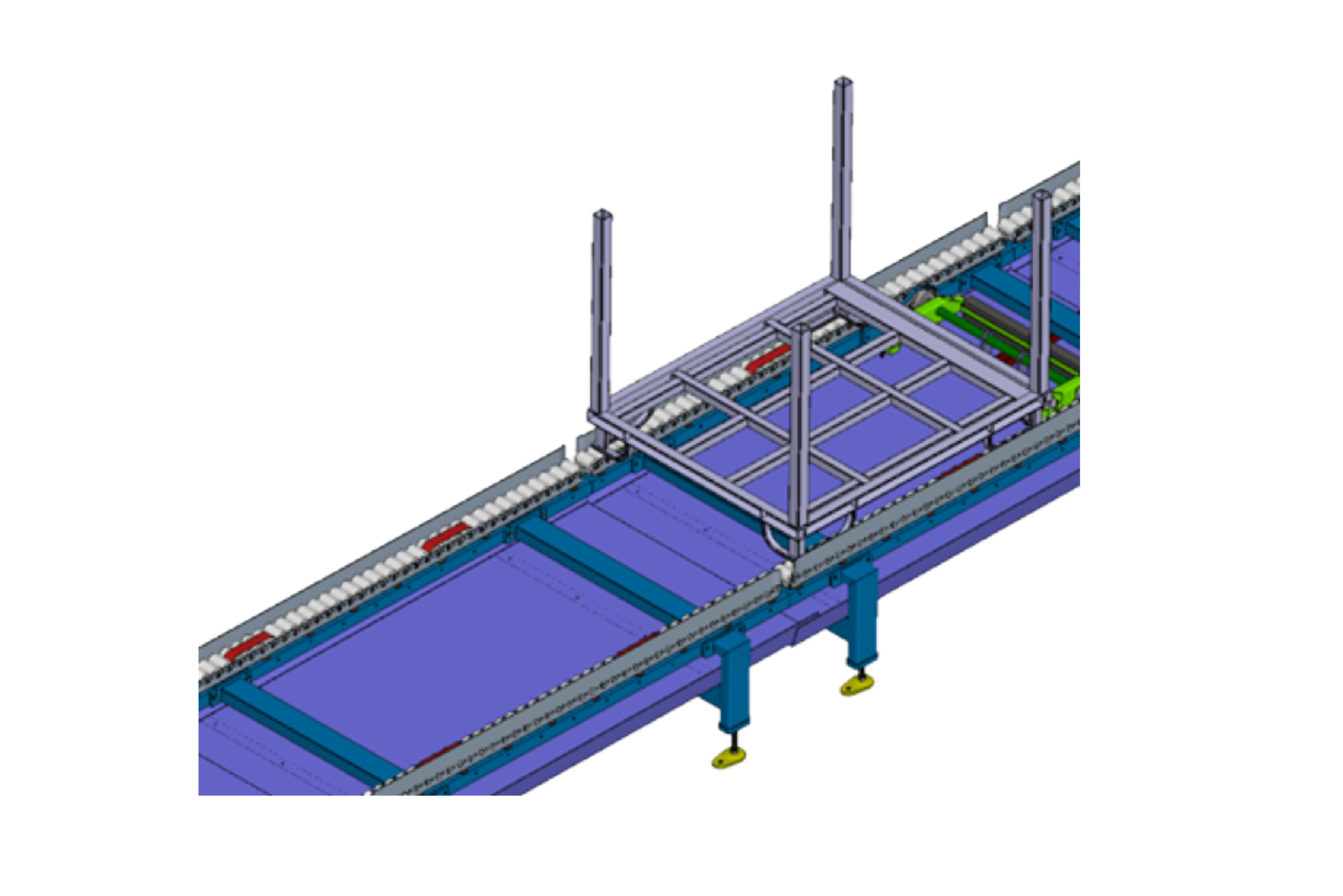

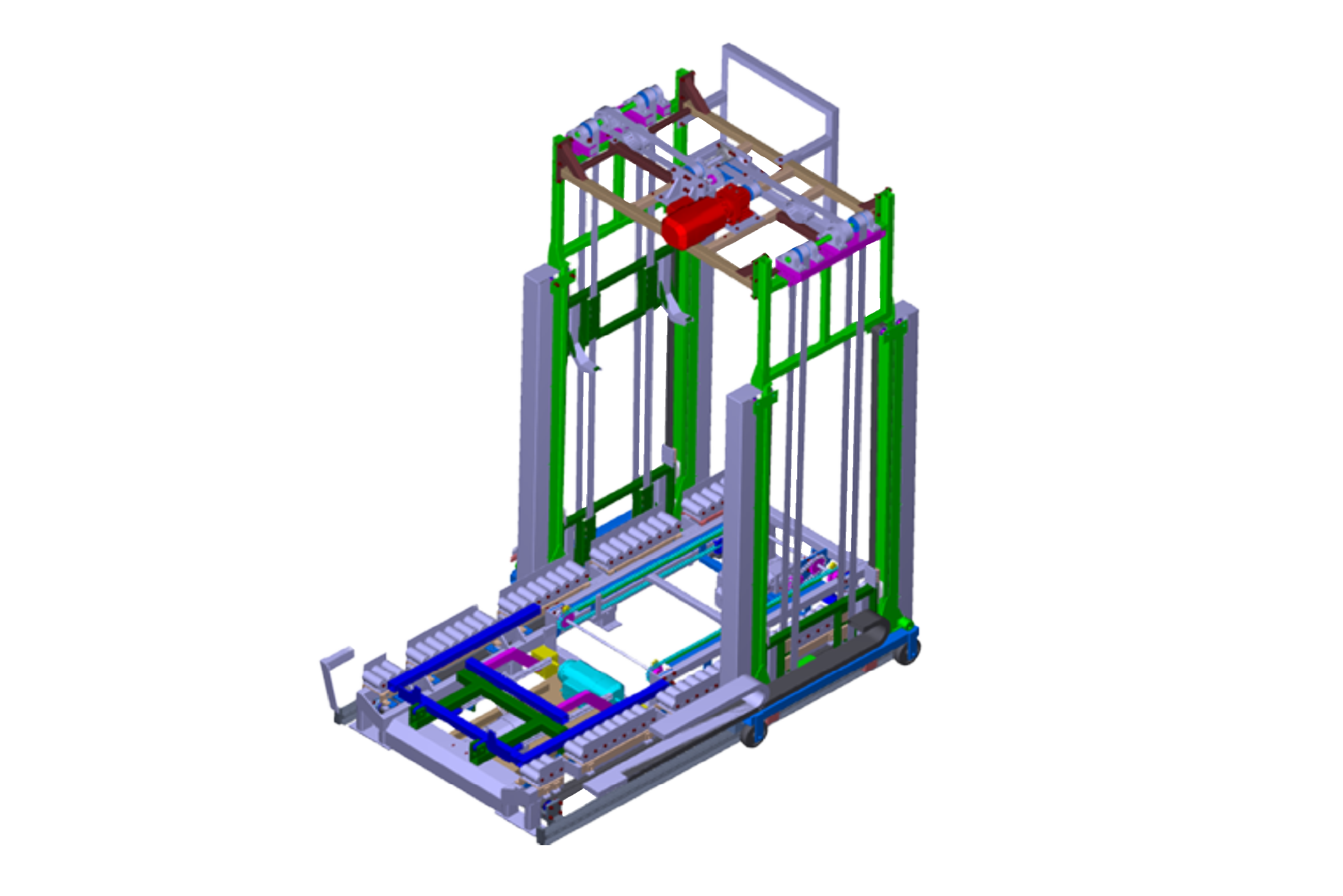

The roller conveyors and transverse movers are stationary systems for the provision of goods grouped in containers. Workers can maneuver the container without much effort and empty containers can be exchanged for full containers.